Advantages of the movable, overflow and underflow hydropower plant

Hydropower is one of the most important sources for renewable energy in Germany. According to a study of the German Ministry for the Environment, however, the use of hydropower for the production of energy is not always considered appropriate. Therefore hydropower plants should not be built or put back into operation in near-natural rivers or rivers that can be naturally regenerated. According to the Ministry for the Environment, there are no concerns regarding the construction and reactivation of plants in existing weirs that cannot be revitalized. This is particularly true if ecological improvements (e. g. re-establishment of fish passability) are achieved simultaneously and the interests of water conservation and flood prevention are additionally taken into account.

The innovative nature of the movable hydropower plant of overflow and underflow type is mainly the fact that such a simple and quickly constructed facility makes it possible to realize power plant, fish ladders, flood relief and bedload transport. Moreover, the movable power plant can be integrated directly into existing weirs with no need for an additional water diversion.

Prof. Dr. T. Bunge et.al.:„Wasserkraftanlagen als erneuerbare Energiequelle: rechtliche und ökologische Aspekte“ (Hydropower plants used as sources of renewable energy: legal and ecological aspects), a publication of the Federal Environment Agency, January 20

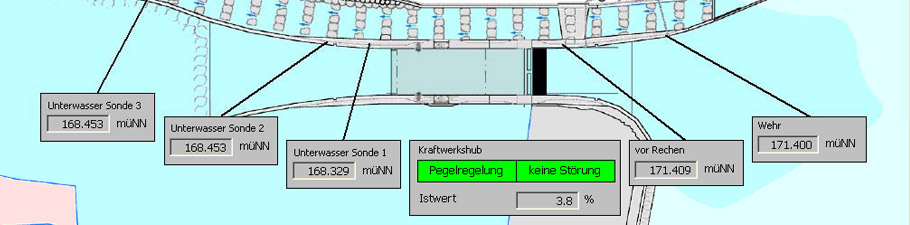

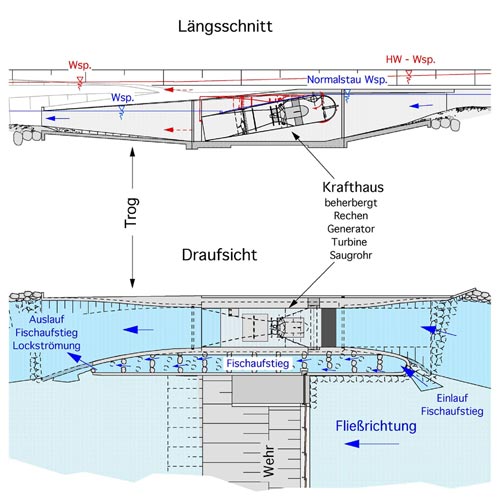

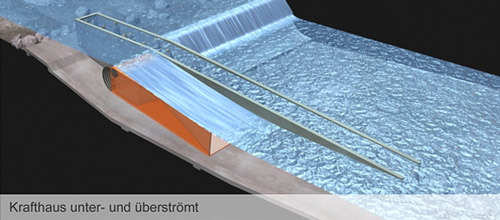

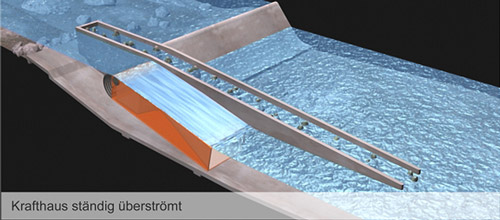

Figure 1: Schematic diagram of a movable hydropower plant of overflow and underflow type

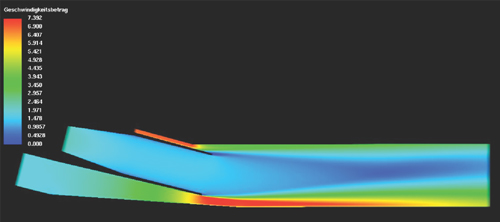

In high water situations, the power plant can be rotated which clears an opening below the turbine housing. This opening can be used to control the backwater level in the pondage, and the ejector effect at the end of the intake tube can be used to increase the energy production. By simulations of the velocity and pressure profiles it was possible to prove this ejector effect already in the previous research and development project which was conducted in co-operation with the Institute for Fluid Mechanics and Hydraulic Machinery of the University of Stuttgart.

Figure 2: Flow pattern illustrating the overflow and underflow

The bedload transport in flood water situations improves the ecological balance in the weir and prevents the silting-up of the water storage area. During a water discharge below the maximum throughput of the turbine a maximum of the potential energy is utilized by the closing of the opening. According to the current state of knowledge, the configuration of the constantly submerged curved bar screen in combination with a constant overflow appears to be an excellent opportunity for fish protection and serves as a fish pass for descending fish in different stages of development that migrate on the surface of the river. A constant or temporary lift of the powerhouse also complies with the demand of a fish pass for fish descending near the river bed. The lifting of the powerhouse avoids the known problem concerning the blockage of eel traps and a possible jam can simply be removed as well. In comparison to conventional systems engineering, fish passes for descending fish can be realized with this plant concept at no additional financial expense. The arrangement of the fish ladder right next to the trough of the plant suggests that the fish will find the access very easily.

Figure 3: Access of the fish ladder right next to the mainstream.

After the completion of the plants the overflow arrangement of the movable powerhouse manages that mainly the fish ladder is visible which is located next to the trough of the power plant and is thus easily traceable for fish. Due to the underwater construction and the abandonment of transmissions of any kind the operation of the power plant will be acoustically hardly perceivable.

Figure 4: movable hydropower plant at Q river

Figure 5: movable hydropower plant at Q river > Q plant

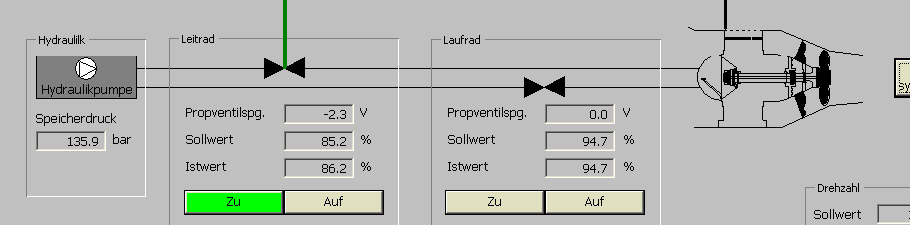

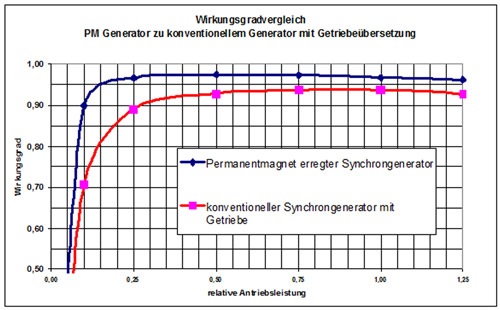

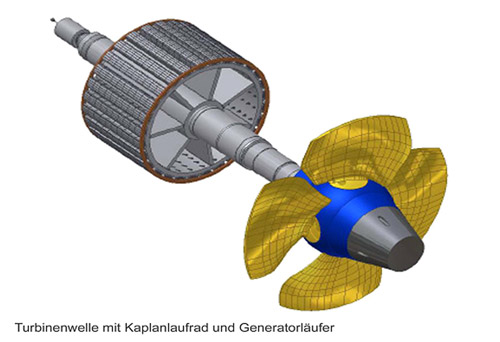

This principle of a hydropower plant does not utilize a gear drive but a low-speed, directly coupled generator instead. This new generator principle in combination with a double-regulated Kaplan turbine has already been tested at a plant supported by the German Ministry for the Environment and was successfully realized in further plants.

The use of permanent magnets to excite the directly coupled synchronous generator reduces losses by approx. 30 % compared to a conventional synchronous generator technology. So even despite the low speed a very high efficiency (> 97 %) can be obtained in particular in part-load operations.

The optimization of the complete hydraulic system leads to a high degree of conversion of the hydraulic primary energy into mechanical energy. By the omission of conversion and of all kinds of cooling systems there will probably be a low operational and maintenance effort.

This total amount of all the above named innovations that are implemented in the movable hydropower plant of overflow and underflow type leads to an increase in energy production of 5 to 15 % per year compared to a conventional plant with the same throughput of the turbine while simultaneously halving the operating and maintenance costs.